The Core Role of OEM in Custom Apparel Industry

In the dynamic global custom apparel market, Original Equipment Manufacturer (OEM) has become a cornerstone model that connects brand creativity with manufacturing expertise. For brands, startups, and entrepreneurs aiming to launch unique apparel lines, understanding OEM services is essential to unlocking efficient production and brand differentiation. As a professional player in the custom apparel field, Gahumi is committed to demystifying OEM in custom apparel factories, helping clients leverage this model to turn design concepts into high-quality, market-ready products. This article will delve into the definition, core characteristics, operational processes, advantages, and selection criteria of OEM in custom apparel manufacturing, while integrating Gahumi’s service advantages to provide practical insights for industry practitioners.

Defining OEM in Custom Apparel Manufacturing

OEM, short for Original Equipment Manufacturer, refers to a production and business model where a manufacturing enterprise (the OEM factory) produces products strictly in accordance with the design schemes, technical specifications, and quality requirements provided by the brand party (the entrusting party), and the finished products are ultimately sold under the brand party’s logo instead of the manufacturer’s own brand. In the context of custom apparel, this model embodies a clear division of labor: the brand party focuses on design innovation, market positioning, and brand operation, while the OEM factory undertakes the specific production links such as fabric sourcing, cutting, sewing, printing, and finishing.

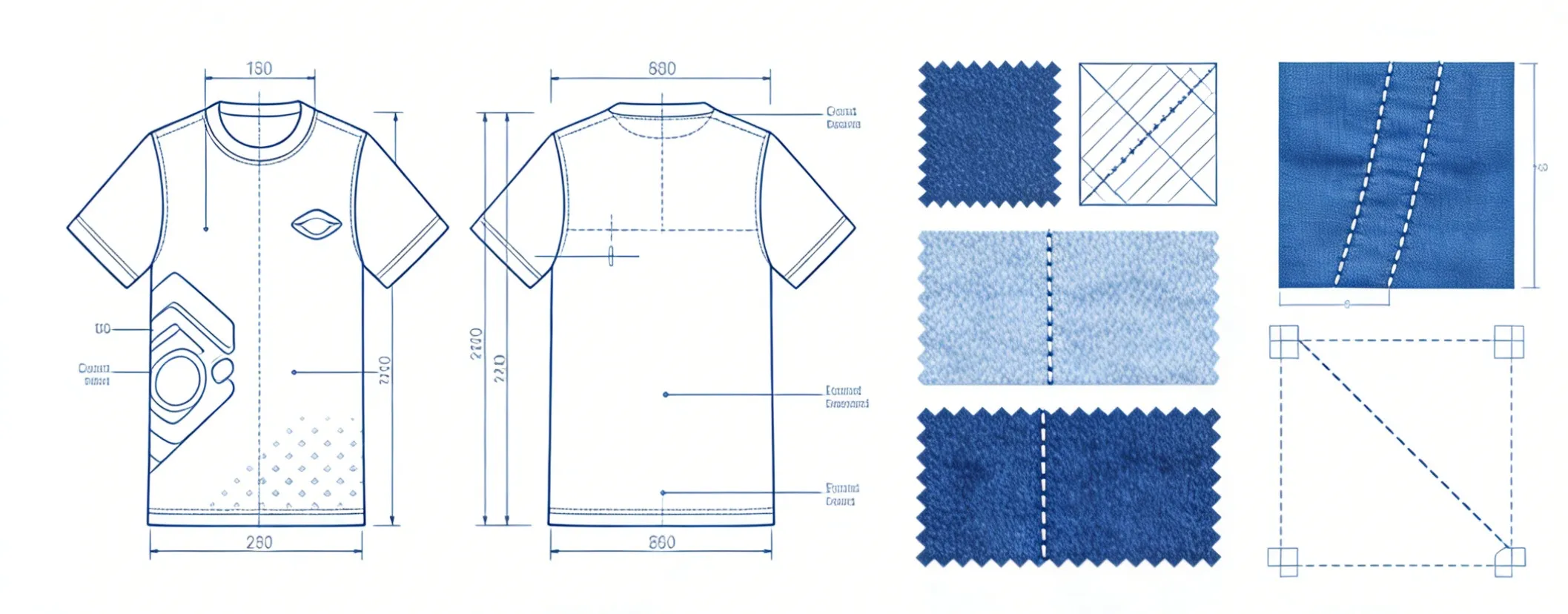

It should be emphasized that OEM in custom apparel is not a simple "processing on behalf" but a comprehensive cooperative partnership based on precise customization. Unlike ODM (Original Design Manufacturer) which provides pre-designed styles for brands to modify, OEM grants the brand complete creative control—every detail from fabric type, color matching, and size standards to printing craftsmanship and packaging design is determined by the brand, and the OEM factory’s core responsibility is to accurately implement these requirements. For example, when a sports brand intends to launch a custom sublimation T-shirt for children, it only needs to provide Gahumi with detailed design drawings, fabric specifications (such as 100% polyester of 140g weight), printing requirements (such as dyed sublimated printing), and size standards, and Gahumi will complete the entire production process and deliver products that meet the brand’s branding requirements.

Core Characteristics of OEM Services in Custom Apparel Factories

Full Creative Control for Brands

The most prominent feature of OEM in custom apparel is that the brand party holds absolute dominance in the design link. Brands can rely on their own market insights and design teams to create unique styles that match their brand positioning, without being restricted by the pre-designed styles of the manufacturer. This is particularly important for fashion brands with a clear brand identity, sports brands that need functional apparel customization, and startups that want to stand out in the market with differentiated products. Gahumi fully respects the creative needs of brands, accepting customized requirements for various apparel types such as T-shirts (O-neck, V-neck, lapel), hoodies, and sportswear, and ensuring that each design detail is perfectly presented in the finished product.

Precision in Technical Implementation

OEM custom apparel production requires strict adherence to technical specifications. The brand party usually provides a complete "tech pack" (technical package) including design drawings, fabric samples, size tables, craftsmanship requirements, and quality standards, and the OEM factory must carry out production in strict accordance with this package. This puts high demands on the factory’s technical capabilities and quality control system. Gahumi has rich experience in handling various technical requirements, such as silk screen printing, heat transfer printing, digital printing, and embroidery processes for custom apparel, and can ensure the consistency and stability of product quality through standardized production processes and strict quality inspection procedures.

Flexible Customization of Production Links

OEM services in custom apparel factories cover a full range of production links, and can provide flexible supporting services according to the actual needs of the brand. From fabric sourcing (the factory can source materials that meet the requirements on behalf of the brand or use the materials provided by the brand) to sample production (providing free stock samples and custom sample production services) and bulk production, as well as subsequent packaging and labeling customization, the OEM factory can provide one-stop solutions. Gahumi, for example, offers flexible sample policies—free of charge for stock samples, and the cost of custom design samples is determined based on the logo and specific requirements, which greatly reduces the trial-and-error cost for brands in the early stage of product development.

Clear Division of Labor and Win-Win Cooperation

The OEM model realizes the rational allocation of resources through clear division of labor. The brand party can save a lot of investment in building factories, purchasing equipment, and training production teams, and focus limited resources on core links such as product research and development, brand promotion, and channel expansion. The OEM factory, on the other hand, relies on professional production capabilities to obtain stable orders, realize economies of scale through large-scale production, and continuously improve production efficiency and craftsmanship level. This win-win cooperation model has become an important driving force for the development of the global custom apparel industry.

The Operational Process of OEM in Custom Apparel Factories

The OEM production process of custom apparel is a systematic project that requires close cooperation between the brand party and the OEM factory. Taking Gahumi’s service process as an example, it is mainly divided into the following six key stages:

Demand Communication and Program Confirmation

This is the initial stage of cooperation. The brand party communicates with the OEM factory (Gahumi) about its customization needs, including apparel type, design concept, fabric requirements, craftsmanship details, order quantity, delivery time, and budget. Gahumi’s professional team will sort out the needs, provide professional suggestions (such as fabric selection based on the use scenario of the apparel), and initially confirm the cooperation plan.

Provision of Technical Documents and Sample Making

The brand party provides a complete tech pack to Gahumi. After receiving the technical documents, Gahumi’s technical team will review the rationality of the design and technical requirements. If there are problems such as inconsistent size standards or impractical craftsmanship, it will communicate with the brand party in a timely manner to adjust. After the review is passed, Gahumi will start making samples according to the requirements. For stock samples, it can be provided free of charge; for custom samples, the sample cost will be quoted based on the logo and design complexity, and the sample will be delivered to the brand party for confirmation within the agreed time.

Sample Confirmation and Order Placement

The brand party conducts a comprehensive inspection of the sample, including design accuracy, fabric quality, craftsmanship level, and size fit. If modifications are needed, Gahumi will adjust and re-make the sample according to the feedback until the brand party confirms that the sample meets the requirements. After the sample is confirmed, both parties sign the formal cooperation contract, and the brand party pays the deposit to confirm the order.

Material Sourcing and Incoming Inspection

According to the confirmed sample and technical requirements, Gahumi conducts centralized sourcing of fabrics, accessories (buttons, zippers, labels), and printing materials. All incoming materials will go through strict quality inspection to ensure that they meet the brand’s requirements and relevant industry standards (such as environmental protection standards for fabrics). If the brand party provides materials by itself, Gahumi will also conduct incoming inspection on the provided materials to ensure that they can meet the production needs.

Bulk Production and Quality Control

After the materials are confirmed to be qualified, the bulk production work is officially launched. Gahumi adopts standardized production lines to carry out cutting, sewing, printing, embroidery, and other processes in an orderly manner. During the production process, a full-process quality control system is implemented—special inspectors conduct random inspections at each production link (such as cutting accuracy, sewing density, and printing clarity) to ensure that the quality of each product is consistent with the confirmed sample. At the same time, Gahumi will timely feed back the production progress to the brand party to ensure that the brand party grasps the production dynamics.

Finishing, Packaging and Delivery

After the bulk production is completed, the finished products go through processes such as ironing, sorting, and final quality inspection. Unqualified products are sorted out and handled in accordance with the contract. Qualified products are packaged according to the brand’s requirements (such as custom brand labels, packaging boxes, and shipping marks). After the packaging is completed, Gahumi arranges logistics and transportation according to the agreed delivery method, and delivers the goods to the designated location of the brand party. At the same time, relevant documents such as product inspection reports are provided to ensure the smooth receipt of goods by the brand party.

Advantages of Choosing OEM Services for Custom Apparel Brands

Reducing Operational Costs and Improving Efficiency

Building an in-house production line requires a huge investment in fixed assets, including factory construction, equipment purchase, and personnel training. By choosing OEM services, brands can avoid these high upfront investments and convert fixed costs into variable costs (production costs based on order quantity). According to industry data, OEM models can help brands reduce production costs by 20-30% compared with in-house manufacturing. At the same time, professional OEM factories have mature production processes and supply chains, which can greatly shorten the product launch cycle and help brands quickly respond to market changes.

Ensuring Product Quality and Professionalism

Professional OEM custom apparel factories (such as Gahumi) have rich production experience, advanced production equipment, and strict quality control systems. They are familiar with various fabrics and craftsmanship characteristics and can accurately implement the brand’s design requirements. Many OEM factories have passed international certifications such as ISO 9001:2015 and BSCI, ensuring that product quality meets international standards. For brands that lack professional production experience, choosing OEM services can effectively avoid quality risks and ensure the stability of product quality.

Focusing on Core Competencies and Enhancing Brand Competitiveness

The core competitiveness of most apparel brands lies in design innovation, brand operation, and market channel development. By outsourcing production links to OEM factories, brands can free up more time and resources to focus on these core links—continuously optimizing product designs, strengthening brand promotion, and expanding sales channels. This helps brands establish a unique brand image in the market and enhance their core competitiveness.

Flexibly Responding to Market Demands and Reducing Risks

The fashion industry has the characteristics of fast style updates and strong market volatility. OEM services allow brands to flexibly adjust production quantities according to market demand—when the market demand is strong, they can increase orders; when the market demand is sluggish, they can reduce orders, avoiding the risk of inventory backlogs caused by in-house production. At the same time, OEM factories can quickly adjust production plans according to the brand’s needs, helping brands launch new products in a timely manner and seize market opportunities.

How to Choose a Reliable Custom Apparel OEM Factory: Gahumi’s Advantages

Choosing a reliable OEM factory is the key to the success of custom apparel brands. When selecting an OEM partner, brands should consider multiple factors such as production capacity, technical level, quality control, service level, and sustainability. As a trusted custom apparel OEM service provider, Gahumi has obvious advantages in the following aspects:

Rich Customization Experience and Professional Technical Team

Gahumi has long been engaged in the custom apparel OEM business, with rich experience in serving brands from various industries (such as sports, promotions, gifts, and events). It has a professional team composed of designers, technical personnel, and quality inspectors who are proficient in various apparel production processes and can accurately understand and implement the brand’s customization needs. Whether it is complex printing craftsmanship or strict size requirements, Gahumi can provide professional solutions.

Diversified Customization Capabilities and Flexible Production Support

Gahumi provides a full range of custom apparel OEM services, covering various types of apparel such as T-shirts, hoodies, sportswear, and children’s clothing. It supports multiple printing and embroidery processes, and can customize fabrics of different materials and specifications (such as 100% polyester of 120g-200g) according to the brand’s needs. At the same time, Gahumi has flexible minimum order quantity (MOQ) requirements, which can meet the customization needs of both large brands and small and medium-sized startups, and provides free stock samples to help brands reduce the cost of early exploration.

Strict Quality Control System and International Certification

Gahumi adheres to the principle of "quality first" and has established a complete quality control system covering the entire process from material incoming inspection to finished product delivery. All products are produced in accordance with international quality standards, and relevant certifications can be provided according to the brand’s needs. This ensures that every batch of products delivered by Gahumi meets the brand’s quality requirements and can pass the quality inspection of various markets.

Perfect Service System and Timely Communication

Gahumi provides one-stop OEM services, from demand communication and sample making to bulk production and logistics delivery, with a dedicated person responsible for the whole process. During the cooperation process, it maintains timely and effective communication with the brand party, feeds back the production progress and related problems in a timely manner, and provides professional solutions. After-sales service is also in place—if there are quality problems with the products (non-human factors), Gahumi will actively cooperate with the brand party to solve them.

Focus on Sustainability and Green Production

In response to the global call for sustainable development, Gahumi actively promotes green production concepts, adopts environmentally friendly fabrics and printing materials as much as possible, reduces energy consumption and environmental pollution in the production process. For brands that focus on sustainable development, Gahumi can provide customized green OEM solutions to help brands establish a positive brand image.

OEM as a Catalyst for the Development of Custom Apparel Brands

In the custom apparel industry, OEM is not just a production model, but a strategic tool that helps brands realize resource optimization allocation and value upgrading. By cooperating with professional OEM factories, brands can focus on their core competencies, reduce operational costs, ensure product quality, and quickly respond to market demands. As a professional custom apparel OEM service provider, Gahumi is committed to providing high-quality, personalized OEM services for global brands with its rich experience, professional technology, and perfect service system, helping brands turn design dreams into market reality.

Whether you are a well-known brand planning to expand your custom apparel line, a startup preparing to launch your first apparel product, or an enterprise in need of custom promotional apparel, Gahumi’s OEM services can meet your personalized needs. Choose Gahumi, and let us

.webp)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Tshirt

Tshirt

Custom Hoodie & Sweat

Custom Hoodie & Sweat

Custom Bags

Custom Bags

Flag

Flag

Towel

Towel

Custom Scarf

Custom Scarf

Cap

Cap